Significant Milestone At Liverpool

10 December 2014

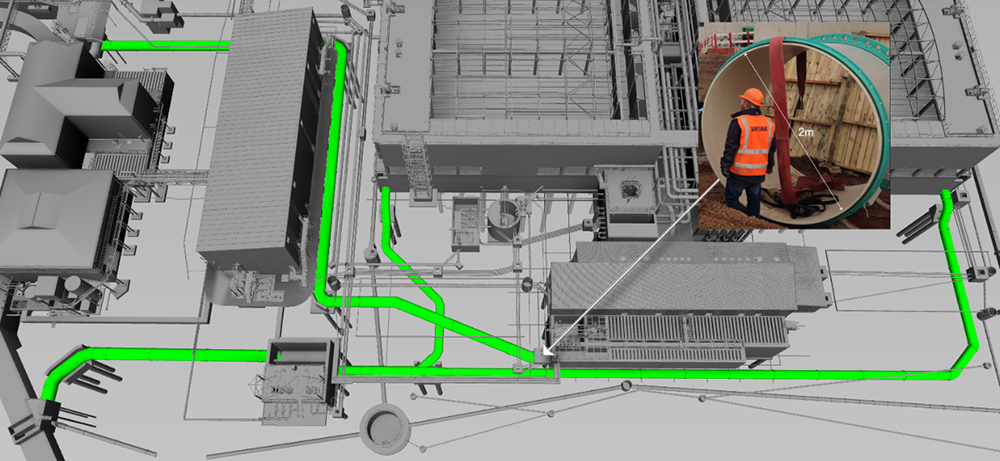

The Galliford Try–Costain–Atkins Joint Venture (GCA JV), a United Utilities AMP5 Process Alliance Partner, recently achieved a significant milestone on the £200 million Liverpool Programme by successfully completing almost 400 metres of very large diameter, fabricated steel and ductile iron pipework, all with the help of Building Information Modelling (BIM).

Any on-site cutting was forbidden due to the coating on the fabricated steel pipework, therefore the installation contractors were anxious that such a large diameter network, often running to hundreds of metres with fixed points, could be laid without major on site modifications.

However, the project employed BIM throughout, enabling the design and construction team to install the pipework, often ranging from 1,600mm to 2,200mm in diameter, to extremely close tolerances. “We couldn’t have achieved the levels of fabrication accuracy without the co-ordinated 3D BIM model. Fabricating steel pipe at very large diameters to the required accuracy is a difficult process, starting out with accurate dimensional data and following it through with a structured checking system lead to project success,” said GCA JV Senior Civil Engineer, Patrick Wills.

Utilising the granularity of the 3D BIM model, the design team modelled a conceptual layout, for review. Once pipe materials had been finalised, and both internal and external diameters established, the layout was rationalised and the 3D model revised to include wall thicknesses and joint details, including the gaps at the joints.

Careful consideration was also given to circularity and diameter tolerances, matching different pipe materials and ensuring that couplers fitted perfectly, albeit within a +/- 5mm circular pipe tolerance. “Constructing the large diameter pipework was a collaborative process from start to finish. Using BIM, along with the early involvement of the construction team, enabled us to not only value engineer the scheme, but to also plan for the safe installation of the large sections of pipework and the precise placement of each individual fitting,” said Gregory Hood, GCA JV Senior Engineer.

A copy of the federated 3D BIM model was issued to the pipework supply contractor, who was able to interrogate it for exact dimensions, to enable completion of 2D fabrication drawings, which were then returned to the GCA design team for checking. Each individual fitting was then extracted from the model, rotated to horizontal and flattened to check the two versions against each other. Following check completion and sign off, the go ahead was given for fabrication of the fitting.

Working closely with the 3D BIM design team, GCA Site Engineering carefully monitored each invert level and centreline co-ordinates at joint locations. With the design team able to interrogate the model at any point during the construction phase, site supervisors were provided with all the information they required to replicate the model exactly.

Ends

Media Enquiries

Costain Communications Department

01628 842585

[email protected]