Novel dissolution technology to accelerate decommissioning

Fuel element debris is a major source of legacy radioactive intermediate level waste. Dissolution in nitric acid facilitates a 95% volume reduction of this waste, significantly reducing long term storage costs.

- Service 1

Magnox Ltd

- Service 1

Consultancy & advisory

Complex programme delivery

- Service 1

IChemE Young Engineer of the Year Award for Costain engineer

3 consecutive RoSPA Silver Awards for Occupational Health and Safety

Key Benefits

95%

reduction in waste volume reduces cost for long term storage

Integrated team

Close working relationship developed between customer and Costain, facilitating efficient project delivery

Fit for purpose

Compliance with regulator requirements without over engineering

Novel nitric acid technology

Substantially accelerates FED dissolution process

Accelerated waste treatment

Dissolution of fuel element debris (FED) in acid provides a means to significantly reduce the hazards associated with Bradwell's inventory of contaminated waste. Dissolution using nitric acid accelerates processing due to an increased reaction rate over previously used carbonic acid.

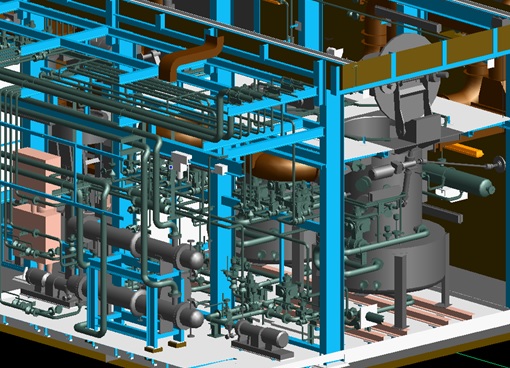

Costain have worked closely with Magnox Ltd to provide a fit for purpose solution using nitric acid, addressing key challenges without introducing undue complexity. Specific services provided on the project include:

- Research & development management

- Concept and front end engineering design

- Detailed design and engineering

- Engineering schedule and design substantiation

- Procurement

- Construction

- Inactive and active commissioning.

Key Challenges

During dissolution of the FED, a significant quantity of heat, hydrogen and NOx is liberated. It is important that excess heat can be removed during operation and that the reaction can be terminated safely under fault conditions.

Costain designed, procured and installed a novel reaction vessel system which allows the FED to be contacted by acid flowing upwards through a perforated basket. In the event of a fault, the reaction is quickly terminated by draining the acid from the basket to separate the acid from the FED.

To maintain safe temperature levels, acid is allowed to overflow from the basket into a lower chamber. From here it is pumped through an external heat exchanger for cooling before being returned to the reaction basket. This straightforward design ensures that heat can be removed whilst maintaining a closed system.

An abatement system was also required to deal with the significant quantity of NOx given off during reaction. Costain reviewed best available technology and developed the detailed design for a hydrogen peroxide / nitric acid scrubber system to reduce NOx emissions to specified levels.

Key safety features were incorporated into the design to minimize any risks associated with hydrogen:

- Reaction termination by draining acid in response to high hydrogen and temperature.

- An emergency back-up system to maintain ventilation in the event of electrical failure. Costain designed an air motor with independent air supply to drive the ventilation fan.

- An independent SIL rated shutdown system designed in accordance with IEC 61508 / 11

Remote Handling

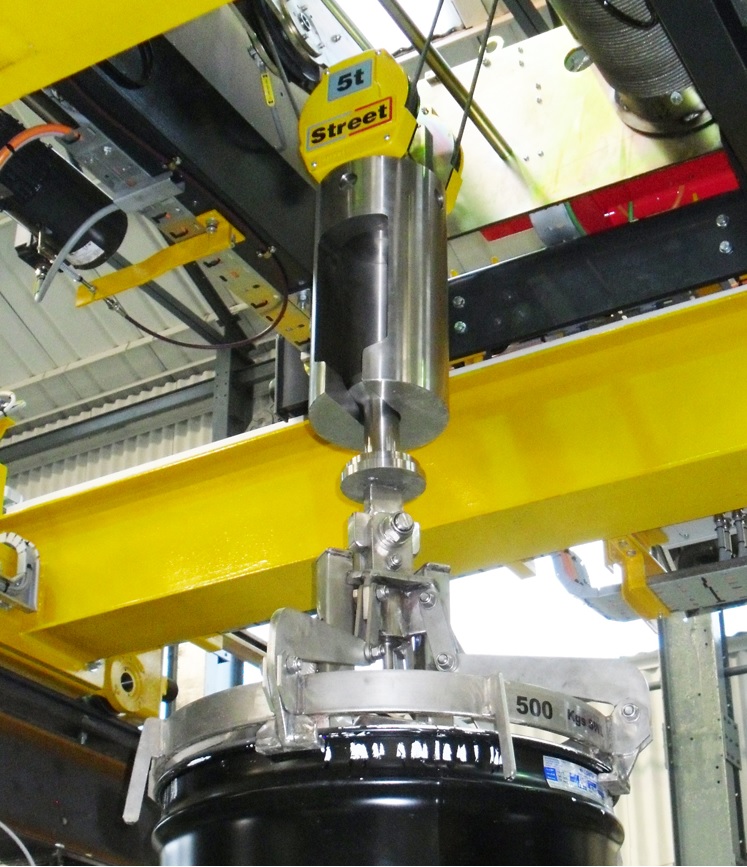

A remote handling system was required to retrieve the FED from 60kg storage containers, load the reaction vessel and remove the remaining intermediate level waste from the reactor basket following dissolution.

Costain designed the plant layout around a single semi-automatic FED Retrieval Crane, allowing it to perform multiple remote handling operations throughout the facility, thus maximizing value. Any remaining remote handling operations that could not be carried out by the Retrieval Crane were incorporated into the Basic Process Control System (BPCS), designed in-house by our experienced C&I engineering team.

Successful project delivery

FED dissolution in nitric acid had not been demonstrated at full scale. It was vital that flexibility existed in the design whilst avoiding complexity. Our collaborative approach allowed development of a design which addresses all associated risks and its success represents a vital step forward in Magnox accelerated decommissioning strategy.

Tackling challenges associated with radioactive waste disposal and significantly reducing the volume of waste through effective dissolution of Fuel Element Debris is a critical element of Magnox decommissioning programme. The solution provided by Costain has enabled Magnox to deliver safe clean-up for the NDA.

Contact and social

Energy